October 22, 1967, the Green Bay Press-Gazette

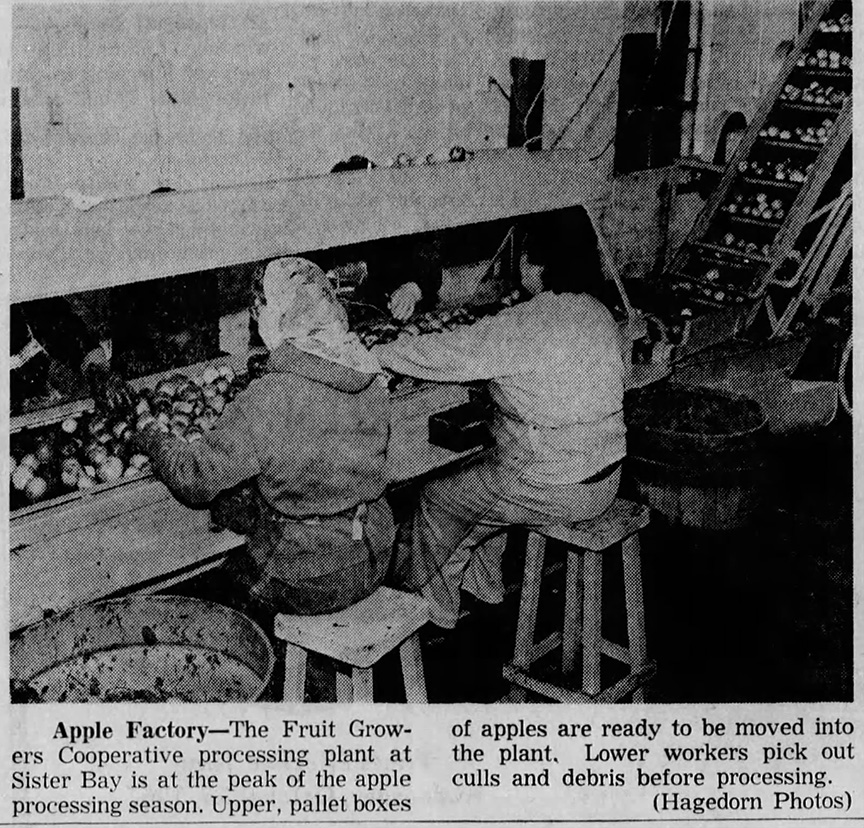

“That’s a lot of apple sauce!” – visitors to the Fruit Growers Cooperative processing plant in Sister Bay may be heard to remark – and they’re right.

The cans, each holding a pound of the pink sauce, come off the line at the rate of about 85 per minute, and the plant, now at the peak of processing, will run an estimated five million pounds by the end of the season, which is around Christmas.

It’s a good year for apples, and although the crop is only a little over half of normal, prices are high, and growers are happy.

This is the second year of operation for the Sister Bay plant, which was expanded after the Sturgeon Bay facilities of the cooperative were sold. Manager Bill Wilson said it has been an extremely successful two years.

The Fruit Growers Cooperative had been a part of the Sturgeon Bay scene since the late 1920s when it came into existence through a merger of Fruit Growers Canning Co. and the Door County Fruit Growers Union. The sprawling, gray wooden buildings situated along Sturgeon Bay’s waterfront, home of the Cooperative, were old. Many of them had been there since 1895 when they were a part of the Reynolds Preserving Co.

The operation had become big business. It provided a sales outlet for millions of pounds of cherries and apples each year and gave seasonal employment to hundreds of persons. In 1964, more than 16 million pounds of cherries alone were processed by the Sturgeon Bay plant. The plant was known as the world’s largest cherry canning factory.

However, the next year was an unusual year – the combination of a short crop and a low price caused by an oversupply from the huge 1964 crop – and it forced the management of the cooperative to give its members only 4 cents per pound for their cherries. Other processors were paying over 5 cents and members of the cooperative were dissatisfied.

At that time the board of directors, deciding that the Sturgeon Bay operation was inefficient and obsolete, called a meeting for the purpose of deciding whether to sell the Sturgeon Bay plant and expand its facilities at the Sister Bay station. At the meeting, in February of 1966, members voted unanimously to sell.

However, many of them, discouraged by the 4-cent price under which they could not even meet expenses, refused to sign contracts for their 1966 crop, and membership in the cooperative dropped from 170 to 80.

Shortly afterward, Peterson Builders Inc. purchased the Sturgeon Bay facilities for the expansion of their firm.

Sister Bay Apple Plant Working at Full Capacity:

Now, Wilson said, it was time for the board of directors to take a good look at the situation, analyze it thoroughly, and determine its future course of action. In May of 1966, the move to Sister Bay was begun.

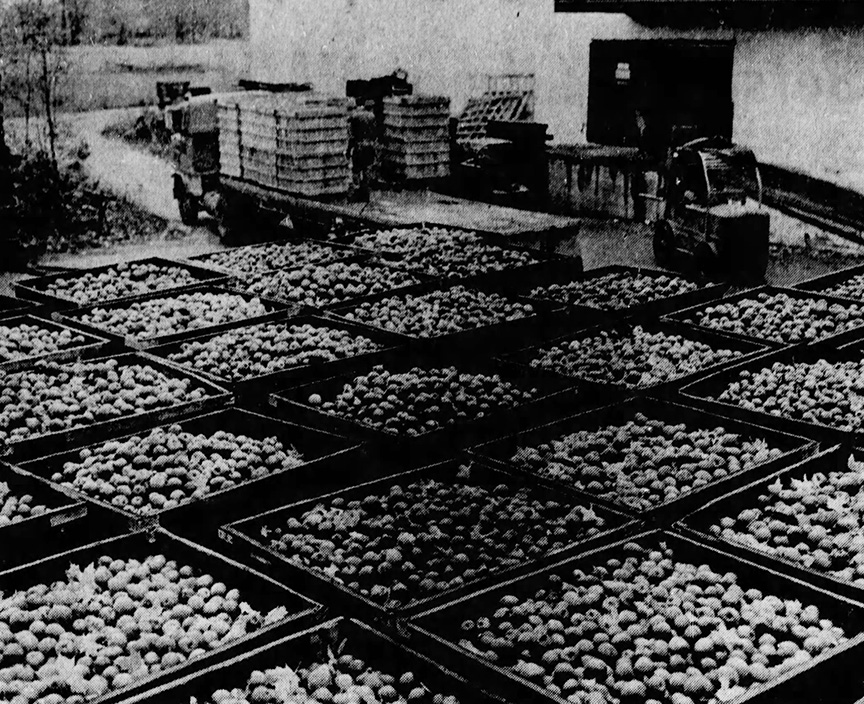

All usable, movable equipment was relocated at the Sister Bay plant, which was expanded to take care of the tonnage estimated for members who had signed their 1966 contracts. Receiving facilities were increased from a capacity of three million pounds to a capacity of about eight million pounds. A warehouse was remodeled to serve as offices. Whatever equipment could not be utilized was sold.

“We are able to process the same items here at Sister Bay that we did at Sturgeon Bay,” Wilson said, “since we have a convertible line.” Cherries are processed for both freezing and cold packing, in three sizes of cans, the No. 303 or 1 pound, the No. 10 or 10 pound, and the 30 pound tins.

It was decided not to can juice, either cherry or apple. The reason, Wilson said, is that the cooperative couldn’t compete with companies set up to process juice in volume.

“Diversification is fine if you’re large enough,” he said adding that some items had to be discontinued in favor of economy.

The cherry plant is completely automated, with electronic sorters and other equipment, requiring much less labor than formerly. In a normal year, Wilson said that plant would process 6-7 million pounds of cherries. “Obviously we didn’t handle that many the past two years, however,” he said referring to the short crop of 1966 and 1967.

Apple sauce is the only apple product processed at Sister Bay and is packed in two sizes – most of it in the No. 303 and some in the No. 10 cans. The entire apple is used for the sauce, and Wilson said it gives a fuller, better flavor, with a soft pink color.

This type seems to be most popular with the homemaker, he said, while institutions are still accustomed to using the white applesauce, made when the apple is peeled, resulting in a blander type of sauce.

Wilson said the cooperative is considering packing sliced apples and may do so next year, but as of yet has not had the volume to warrant the added operation.

Apple processing is so automated that it requires the help of only about six or seven persons. The inferior apples are first culled out, and the apples moved down the line, where they are machine-cut.

They are pressure cooked to retain full flavor, after which the skins and seeds are removed, and sugar added. Then it is re-cooked, packed in cans, sealed, and again sterilized, after which the cans are water-cooled.

Then the cans are labeled and boxed, again by machine, and the boxes are loaded to the warehouse. A new, 20,000-square-foot warehouse was built this year, and Wilson said the entire operation is now totally self-contained. No outside storage is needed.

Wilson is completely satisfied with the adjustment of the cooperative in the transition period which followed the move to Sister Bay, and he said the past two years have been two of the most successful ever. Although the memberships still number only about 80, this year, he said the plant processed fruit for more than 120 growers.

“It was a matter of adjusting the facilities to the tonnage we could expect from our members, creating efficiency and economy of operations,” he said. “We had to learn to take care of our own.”